Whoo hoo! New products are out designed by Design Sharpener! So excited to introduce these designs made with Gaiam and Petwell. We are even listed...

Read MoreTaking your idea all the way yourself: This can be a great route for those inventors who typically have more of a background with producing...

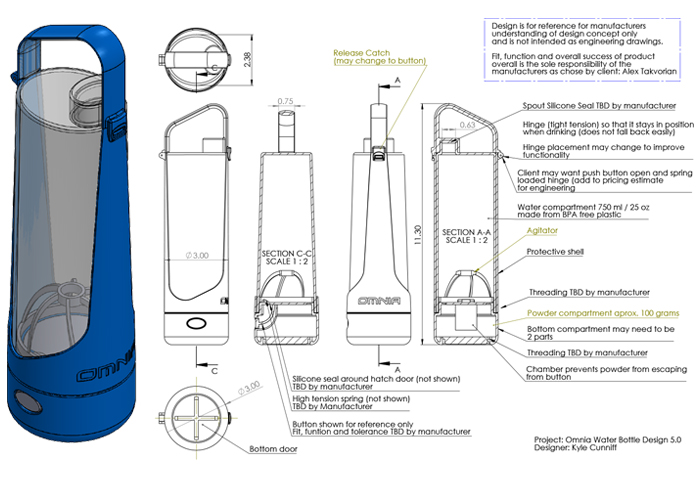

Read MoreThis water bottle tumbler product was designed and engineered in Solidworks. The rendering and animation was done in Keyshot. Its amazing how a professional animation...

Read MoreFor this project I worked on the hole pattern which was punched into the pan. I gave the manufacturing factory a DXF file, or CAD...

Read MoreIn a recent article by IDSA (Industrial Designers Society of America) tried to answer that supremely detailed question all of us industrial designers struggle with,...

Read MoreEco Vessel Glass water bottles are in with a fresh new design, from right here in Boulder, CO. They are easy to clean, dishwasher safe...

Read MoreThis link is posted here as a resource to you to find out more about patent information, how to get a patent, why you should...

Read MoreWinner of the Good Design Award! Ecolution a brand by Epoca got in touch last year with a product they would like to design. They...

Read MoreThis patent resource allows you to conduct a preliminary US patent search, a great starting point if your interested in potentially putting together a patent...

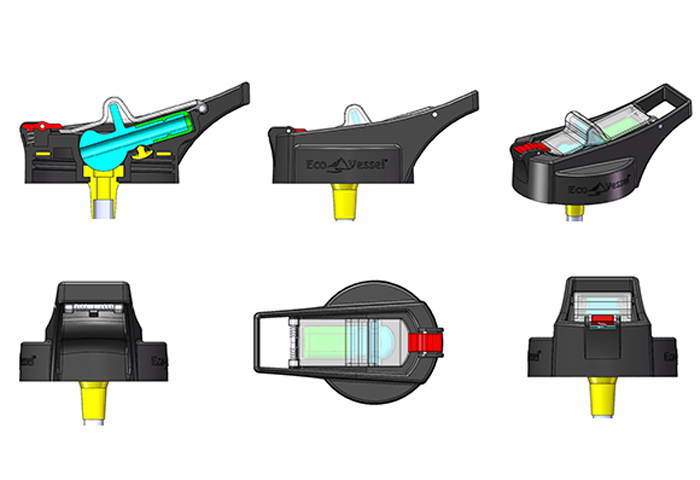

Read MoreThis Pint Glass Sleeve was 3d Modeled in Solidworks. Multiple concepts were presented to the creative team over at Eco Vessel in Boulder, Colorado. I...

Read MoreThis rendering was created using Solidworks and is currently being manufactured for the company Triminator. Below you can see more of my industrial design concept process...

Read MoreOver the summer (a very warm time to be working on a winter sports product) I was contacted by Crescent Moon Snowshoes, a local company...

Read MoreThis video shows off a product design that I created in Solidworks. Using Photoview 360 I was able to create a rendered animation that is...

Read MoreIts the American Dream. You have an idea, you want to make it, sell it and become rich! Where do you start? With me! I...

Read MoreThis short video demonstrates my abilities to make your product vision a reality. We specialize in concept visualization and work all the way from a...

Read MoreBack in January of 2014 in my cozy snow dusted studio in the Foothills of Boulder I sat working on this Spork Product Design project....

Read MoreI use Solidworks for 3d printing functional prototypes for Industrial Design. 3d printing has quickly become the norm for prototyping quick parts and prices have...

Read MoreI can help you with Product Design, Industrial Design, 3d Modeling in Solidworks, Product Rendering and Animation and development for your new big idea! Welcome...

Read MoreWhen I start a new project it is often necessary to create several concept ideations to establish a design direction with the client. This page...

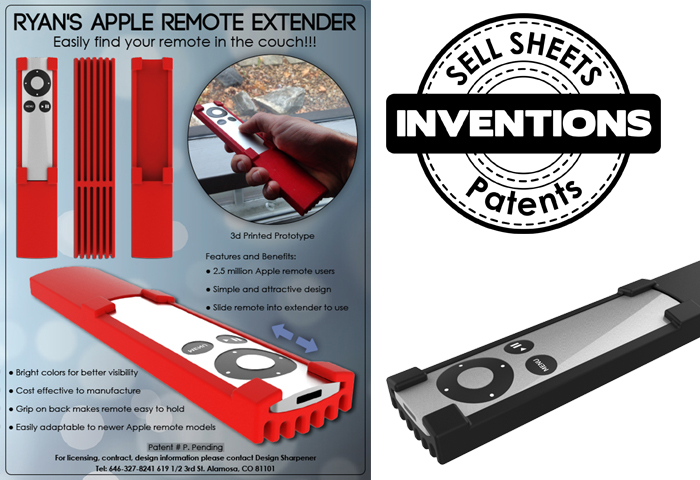

Read MoreIf you cannot convey your ideas in an impactful way, you are dead in the water. That’s the truth! When it comes to product licensing,...

Read More